Turnbuckle Guide: Types, Applications, and Safety Tips

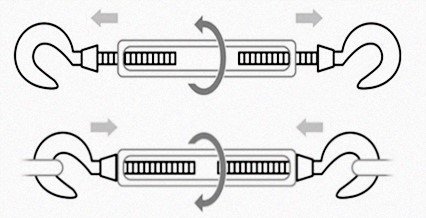

A turnbuckle is a commonly used adjustment device designed to connect and regulate tension. Its simple mechanism allows for precise length adjustments by rotating the central threaded part, which either increases or decreases the distance between connected components, providing accurate tension control. Turnbuckles are widely used in various industries, particularly in construction, marine, hoisting, and industrial applications.

In construction, turnbuckles are used to adjust the tension of cables and wires, ensuring structural stability. In marine applications, they are used to tighten rigging and ropes, maintaining the stability of the vessel. In hoisting operations, turnbuckles control the tension of slings, ensuring safe and efficient lifting. In industrial fields, turnbuckles are essential for adjusting mechanical devices and supporting structures, playing a crucial role in various equipment and engineering projects.

Types of Turnbuckles

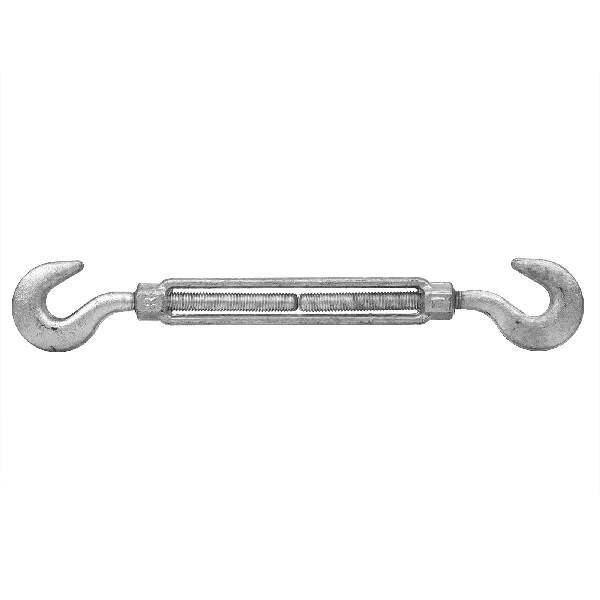

Hook&Hook Turnbuckle

This type features hooks at both ends of the turnbuckle. The hooks are used to secure the turnbuckle to other components such as cables, chains, or lifting equipment.

Eye&Eye Turnbuckle

The eye & eye turnbuckle has eye-shaped loops at both ends, which allow for easy attachment to bolts, pins, or other similar connectors.

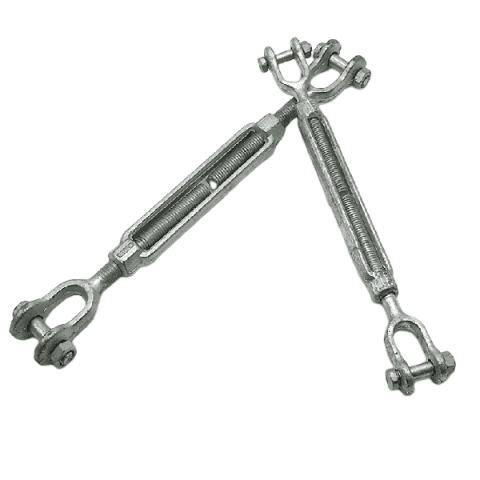

Jaw&Jaw Turnbuckle

This version of the turnbuckle features jaws at both ends, which are typically used to connect to other hardware components such as pins or shackles.

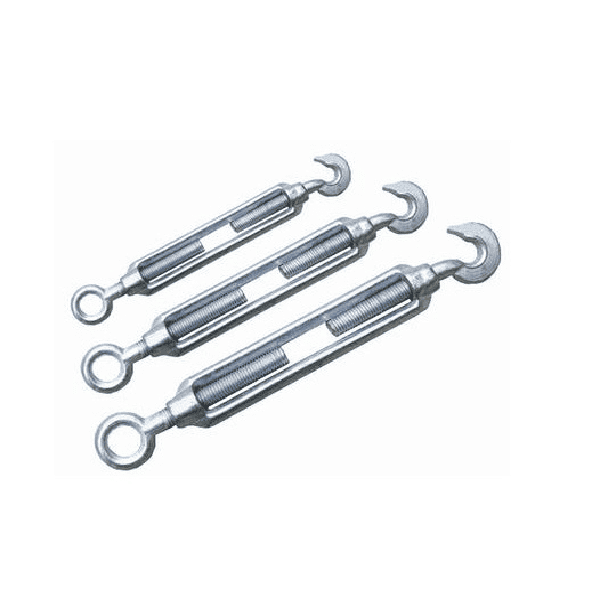

Combination Turnbuckle

A combination turnbuckle features different types of connectors at each end, such as a hook on one end and an eye on the other. This versatility allows it to adapt to various attachment requirements.

Turnbuckles are crucial components in numerous industries, offering precise tension adjustments for a variety of applications.

Versatile Solutions for Various Industries

Construction&Engineering

Turnbuckles are essential for tensioning cables, steel ropes, or supporting structures, ensuring stability in building projects.

Maritime and Offshore

In shipbuilding and offshore operations, turnbuckles help adjust rigging tension, providing necessary stability to sails and other tensioned components.

Outdoor and Agriculture

Whether it’s securing fences or adjusting greenhouse frameworks, turnbuckles offer the flexibility to manage tension, ensuring structural integrity in outdoor environments.

Industrial Applications

Turnbuckles are used in connecting and adjusting mechanical equipment and lifting systems, ensuring smooth operation in industrial settings.

Choose the Right Type and Material

Select the appropriate turnbuckle based on the application’s needs, considering factors such as load-bearing capacity and environmental conditions. Materials like stainless steel are ideal for outdoor or marine environments due to their resistance to corrosion.

Proper Installation

- Ensure turnbuckles are installed correctly by attaching the eye or hook ends to the appropriate rigging points.

- Avoid overtightening: Over-tightening can lead to stress and potential failure. Use a wrench to tighten the turnbuckle, but stop once it is securely in place.

- Avoid lateral forces: Always ensure that the turnbuckle is used in line with the load direction to avoid bending or warping due to sideways tension.

Inspect Before and After Use

Regularly check turnbuckles for signs of wear, corrosion, or damage, especially after heavy use. Any cracks, bends, or rust can compromise its performance.

Common Mistakes and How to Avoid Them

- Over-tightening: As mentioned, this can cause damage to the turnbuckle threads. Avoid using excessive force.

- Incorrect alignment: Always ensure the turnbuckle is installed along the same axis as the tension force to prevent uneven wear or failure.

How to Use Turnbuckles Properly?

Frequently Asked Questions

Here are some common questions about turnbuckles, along with answers to help you understand their function, selection, and maintenance.

A turnbuckle works by using a central threaded mechanism to adjust the length of the connected components. It consists of a body with internal threads and two external connectors (such as hooks, eyes, or jaws) at each end. By rotating the body, the connectors are either pulled together or pushed apart, allowing for precise tension adjustment. This mechanism is used to tighten or loosen cables, ropes, or other elements in a controlled manner, making turnbuckles essential for tensioning and adjusting lengths in various applications.

Choosing the right turnbuckle depends on several factors:

- Type of Connection: Consider whether you need hooks, eyes, jaws, or a combination of connectors based on your specific application.

- Material: Select the material based on the environment and load requirements. Stainless steel is ideal for corrosion-resistant applications (e.g., marine environments), while carbon steel is suited for high-strength and heavy-duty applications.

- Load Capacity: Ensure the turnbuckle’s working load limit (WLL) meets the demands of the task. Always check the manufacturer’s specifications for the correct WLL.

- Size: Choose a turnbuckle that fits your existing cables, chains, or other hardware components in terms of diameter and length.

- Application: Different industries (construction, marine, rigging, etc.) may require specific types of turnbuckles, so make sure to select the appropriate one based on the application.

To ensure the longevity and safe use of your turnbuckle, follow these maintenance tips:

- Regular Inspection: Check for signs of corrosion, wear, or damage to the turnbuckle. Ensure the threads are intact and not stripped, and that the connectors (hooks, eyes, or jaws) are secure.

- Lubrication: Apply a light oil or grease to the threaded part of the turnbuckle to prevent rust and ensure smooth adjustment. This is especially important in harsh environments.

- Cleaning: Clean the turnbuckle after each use, particularly in marine or corrosive environments, to remove dirt, salt, or other contaminants.

- Proper Storage: When not in use, store turnbuckles in a dry, cool place to avoid exposure to the elements. If stored outdoors, consider using protective covers to prevent rusting.

- Avoid Overloading: Always adhere to the turnbuckle’s working load limit (WLL) to prevent strain or failure.