Why Choosing the Right Shackle Matters

Shackles are essential in lifting and lashing operations, but selecting the right shackle for the job is critical to ensuring safety, efficiency, and durability. With different types, materials, and load capacities available, it’s easy to make a mistake that can lead to operational risks.

Common Shackle Types and Their Application

| Shackle Type | Features | Applications | Pros | Cons |

| Bow Shackle | Wide opening, suitable for multi-directional loads | Lifting operations, connecting multiple slings | Handles loads from different angles | Slightly lower load capacity for single-direction loads |

| D shackle | Narrow opening, designed for single-direction loads | Lifting steel beams, securing heavy loads | Higher load capacity for straight pulls | Not ideal for multi-directional loads |

| Screw Pin Shackle | Easy to install and remove, suitable for temporary use | Temporary lifting, outdoor adventure securing cargo | Quick to install | May loosen in vibrating environments |

| Bolt Type Shackle | It Comes with a safety pin, ideal for long-term use | Marine Operations, long-term lifting setups | Secure and resistant to loosening | More complex installation process |

How to Determine the Working Load Limit (WLL)

What is WLL?

The Working Load Limit (WLL) refers to the maximum safe load a shackle can handle under normal operating conditions. The WLL is usually stamped on the body of the shackle.

Matching WLL to Your Load Requirements

Use the table below to match the shackle size with the required load capacity.

| Shackle Size | WLL(Tons) | Application |

| Below 12mm | Below 1.5T | Small equipment lifting |

| 12mm-25mm | 1.5T to 8.5T | Building material lifting |

| Over 25mm | Over 8.5T | Heavy machinery lifting |

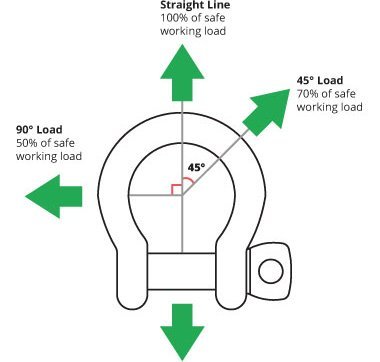

Impact of Load Angle on WLL

The load capacity of a shackle decreases as the angle of the load changes. Ensure you understand how different angles affect the WLL and adjust your setup accordingly.

Material Selection: Galvanized Steel, Stainless Steel, or Alloy Steel?

| Material Type | Features | Applications | Corrosion Resistance |

| Galvanized steel | Economical, moderate corrosion resistance | General lifting, outdoor use | ⭐⭐⭐ |

| Stainless steel | Excellent corrosion resistance, anti-oxidation | Marine operations, Chemical industry | ⭐⭐⭐⭐⭐ |

| Alloy Steel | Higher strength, suitable for heavy loads | Heavy-duty lifting, mining | ⭐⭐⭐⭐ |

Material Selection Tips

- For marine or humid environments: Choose stainless steel shackles for better corrosion resistance.

- For heavy industrial use: Opt for alloy steel shackles for higher strength.

- For general lifting tasks: Galvanized steel shackles offer good value for money.

Shackle Selection for Special Environments

- Marine Operations: Use stainless steel or galvanized shackles with anti-corrosion properties.

- High-Temperature Environments: Avoid shackles with plastic coatings and choose heat-resistant alloy steel.

- Vibrating Environments: Use bolt type shackles to prevent loosening.

Common Mistakes When Choosing Shackles

Mistake 1: Any shackle type can be used for lifting.

👉 In reality, different types of shackles are suited for specific applications, and using the wrong type can pose safety risks.

Mistake 2: WLL is the only factor to consider.

👉 WLL is important, but you also need to consider material, size, and connection method.

Mistake 3: All shackles from different brands are the same.

👉 Always choose products that meet EN 13889 or ASME B30.26 standards to ensure safety and reliability.

Conclusion: How to Choose the Right Shackle for Your Needs

When selecting a shackle, consider the following:

- Type: Choose based on your specific lifting or lashing needs.

- Load Capacity: Ensure the shackle’s WLL matches your load requirements.

- Material: Consider environmental factors like corrosion and temperature.

- Size: Ensure proper fit and compatibility with other equipment.

For special environments, always choose shackles with features that provide extra protection, such as anti-corrosion coatings or vibration-resistant designs

Contact Us

Not sure which shackle to choose? Contact us for a free selection consultation!