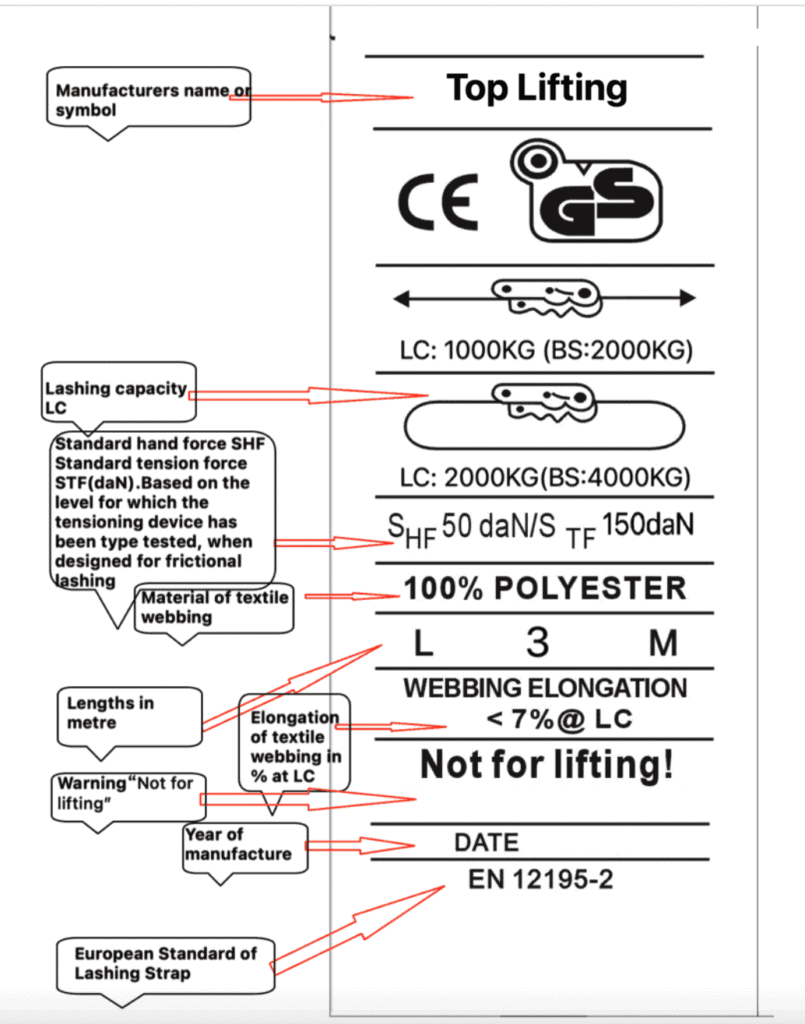

EN12195-2 standard: key to ensuring cargo transportation safety

In cargo transportation, securing goods firmly is fundamental to ensuring safety. Whether by road, rail, sea, or air, the proper use of tensioning belts, lashing straps, and related securing equipment plays a critical role in transport safety. As a key European technical specification for lashing devices, the EN12195-2 standard establishes detailed safety guidelines for cargo securing operations. This article examines the standard’s core provisions, technical requirements, and industry significance, highlighting its essential role in enhancing transportation safety.

What is the EN12195-2 standard?

EN12195-2 is a European safety standard for cargo securing devices, such as straps and tensioning straps, primarily used to ensure cargo safety during transportation. It covers strap selection, usage requirements, load limits, and labeling, providing detailed operational guidance for transport companies and equipment suppliers.

Key points of EN12195-2 standard

Lashing Capacity (LC)

Lashing Capacity (LC) refers to the maximum tensile force a strap or fastening device can withstand. It represents the maximum tensile force a strap can withstand under normal use. LC is a key factor in determining whether a strap can carry the intended load. If the tensile force exceeds the strap’s LC, the strap may damage or break.

Example:

Suppose a strap’s LC is 800 daN, meaning it has a maximum tensile force of 800 dynes. If the tensile force exceeds 800 daN during transport, the strap may break.

Safety Factor (SF)

The SF (Safety Factor) is the ratio between the strength of a strap or anchorage and its lashing capacity (LC). It indicates the margin of strength the strap can withstand under maximum load. A common safety factor is 2:1, meaning the strap’s strength is two times its LC.

Example:

If a strap has an LC of 2,500 kg and an SF of 2:1, the strap’s actual load capacity is 5,000 kg.

STF (Securing Tension Force)

STF (Securing Tension Force) refers to the tension applied by the strapping when securing cargo. It measures the force the strapping exerts to secure the cargo, ensuring it remains secure. A correct STF is crucial for preventing cargo from shifting during transport. If the tension is too low, the cargo may slip during transport; if the tension is too high, the strapping may damage or cause the cargo to deform.

SHF (Stretch Factor)

SHF (Stretching Factor) refers to the amount of stretch a strapping material may experience during tightening. Straps made of different materials will stretch when tension is applied. SHF is a key indicator for assessing this stretch. Common strapping materials (such as polyester) will stretch to a certain extent when tightened, which can affect cargo securing.

Conclusion

The EN12195-2 standard is not only an essential technical specification for cargo transportation but also a key factor in ensuring transportation safety. By adhering to this standard, transport companies can reduce safety risks, improve efficiency, and provide more reliable service to their customers. Both manufacturers and transport companies should pay attention to this standard and ensure that their fixed equipment meets the relevant safety requirements.