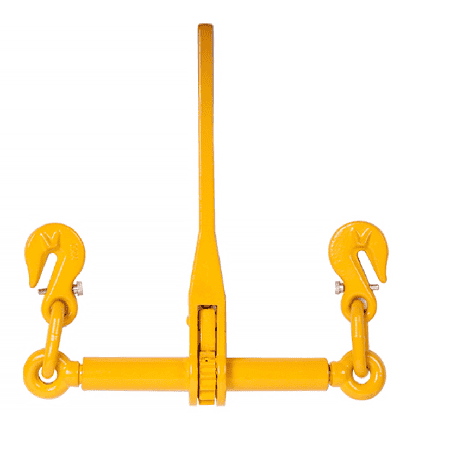

Save your ratchet buckle: Practical tips for rust prevention and lifespan extension

Ratchet buckles are critical components for cargo securing and transport across various industries, where their reliable locking mechanism is paramount to overall safety. However, prolonged exposure to harsh environments like moisture and salt can directly threaten the integrity of their metal parts, leading to rust that compromises performance and poses potential safety risks. This article analyzes the causes of ratchet buckle corrosion and provides a set of effective protection and maintenance strategies to ensure their long-term, reliable operation.

Main Causes of Rust on Ratchet Buckles

Environmental Factors: The Dual Challenge of Moisture and Salt

Humidity and salt are primary external triggers for ratchet buckle corrosion. In coastal regions or during maritime transport, salt spray in the air significantly accelerates the electrochemical corrosion process on metal surfaces. Furthermore, if buckles are stored for extended periods in damp or poorly ventilated areas after use, internal components remain susceptible to rust due to persistent moisture exposure.

Protective Layer Damage: Wear of the Zinc Coating

Most ratchet buckles are zinc-plated to enhance rust resistance. However, in practical applications, frequent friction, contact with cargo, or scraping against rough surfaces can gradually degrade this protective layer. Once the zinc coating is compromised, the underlying steel is exposed to air and prone to oxidation.

Material Selection: The Fundamental Determinant of Rust Resistance

The material composition of the buckle itself is the core factor influencing its corrosion resistance. Low-quality zinc-plated or untreated iron buckles are highly susceptible to rust in humid environments. In contrast, buckles made from materials such as 304 or 316 stainless steel, or those treated with high-quality hot treatment, provide significantly more durable and reliable protection at the fundamental level.

Rust Protection Measures for Ratchet Buckles

Choose the Right Materials

To effectively prevent rust, it’s essential to select the right materials. Stainless steel buckles offer the best rust resistance and are ideal for high-corrosion environments. While blue-white zinc and color zinc coatings provide some protection, they are more likely to lose their anti-rust capabilities if scratched or worn.

Proper Storage Environment

Store ratchet buckles in a dry, well-ventilated area, avoiding prolonged exposure to moisture and salt. After use, ensure the buckle is cleaned and stored away from corrosive substances.

Routine Maintenance for Ratchet Buckles

Regular Inspections and Cleaning

Periodically check the condition of your ratchet buckles for rust, scratches, or damage to the coating. If rust appears on the buckle’s surface, clean it promptly. Use a soft cloth and non-corrosive cleaner to wipe the buckle, avoiding tools that might scratch the surface.

Use Rust-Proof Coatings

To enhance protection, apply rust-inhibiting oil or protective coatings to ratchet buckles regularly. This creates a protective layer that prevents moisture and air from penetrating. For buckles used frequently or exposed to harsh environments, regular coating applications will significantly extend their lifespan.

How to Tell If Your Ratchet Buckle Needs Replacing

If a ratchet buckle shows signs of severe rust and its performance is compromised, it is advisable to replace it immediately. When rust affects the buckle’s locking function or operation, replacing it with a new one is necessary to ensure safety.

Conclusion

By selecting the right materials, performing regular inspections, cleaning, and storing ratchet buckles properly, you can effectively prevent rust and extend their lifespan. Proper rust protection, along with routine maintenance, is key to ensuring your ratchet buckles function reliably and safely over time.