The Ultimate Jack Guide: Selection, Usage & Safety Maintenance

Whether it’s a Hydraulic Bottle Jack, Floor Jack, Toe Jack, Farm Jack, Mechanical Jack, or Jack Stand, this guide will help you understand different types of jacks, choose the right model, and master proper usage and maintenance techniques to ensure safe and efficient operation!

Choosing the Right Jack for Safe & Efficient Lifting

Jacks are essential lifting tools used across various industries, from automotive repair and heavy machinery maintenance to construction and industrial applications. Whether you need to lift a vehicle for routine maintenance, raise heavy equipment for installation, or support loads safely in place, choosing the right jack is crucial for efficiency and safety.

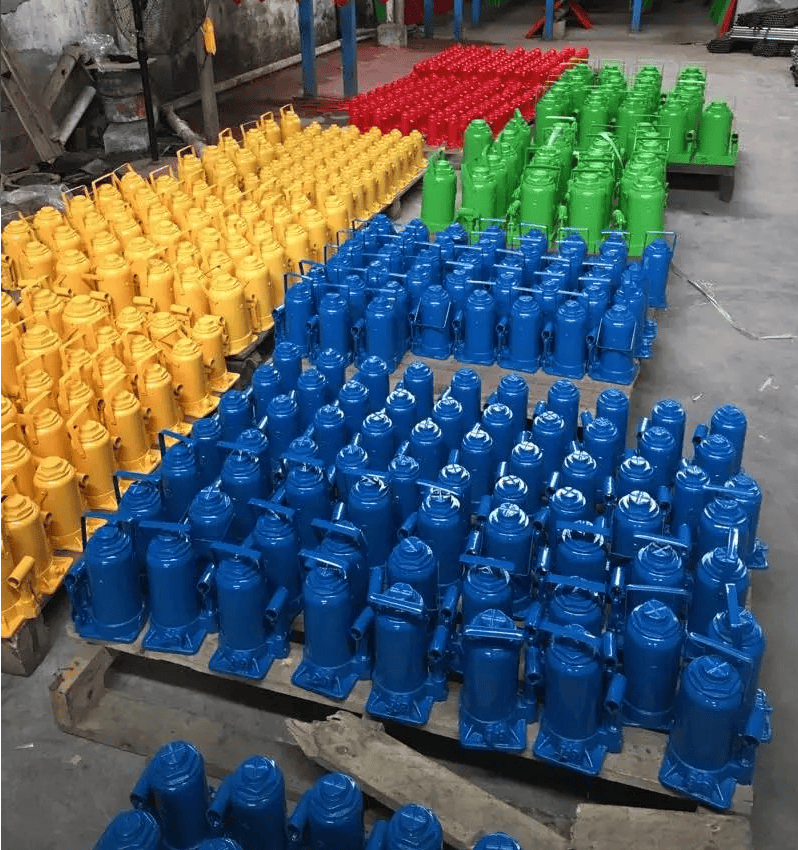

Classification of Jacks

Hydraulic Jacks

Hydraulic jacks use fluid pressure to generate lifting force. They are widely used for their high lifting capacity and smooth operation.

Bottle Jack

- Compact, vertical design with a sturdy base

- Uses hydraulic fluid to lift heavy loads with minimal effort

- Available in different weight capacities

Floor Jack

- Long, low-profile design with wheels for easy positioning

- Faster lifting mechanism compared to bottle jacks

- Ideal for sports cars

- Suitable for vehicles with low ground clearance

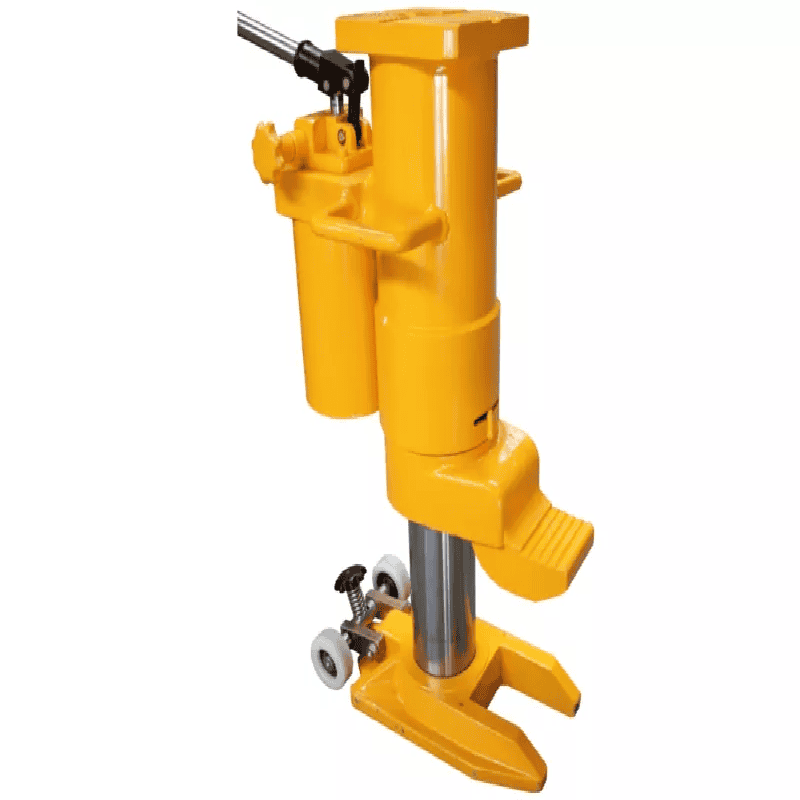

Toe Jack

- Designed with a low-height lifting point (toe) for tight spaces

- High-capacity lifting, often supporting 10+ tons

- Lifting points: toe and head for different applications

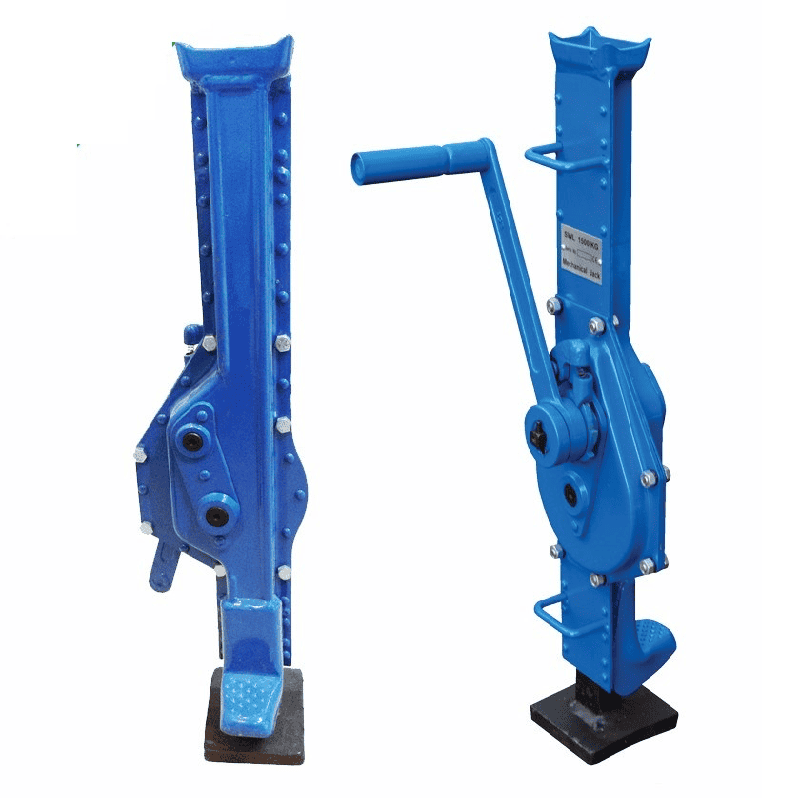

Mechanical Jacks

Unlike hydraulic jacks, mechanical jacks rely on manual operation using a screw or ratchet system. They are known for durability and reliability in industrial and emergency situations.

Mechanical Jacks

- Uses a threaded screw mechanism to lift loads

- Simple, durable, and does not require hydraulic fluid

- Requires more effort compared to hydraulic jacks

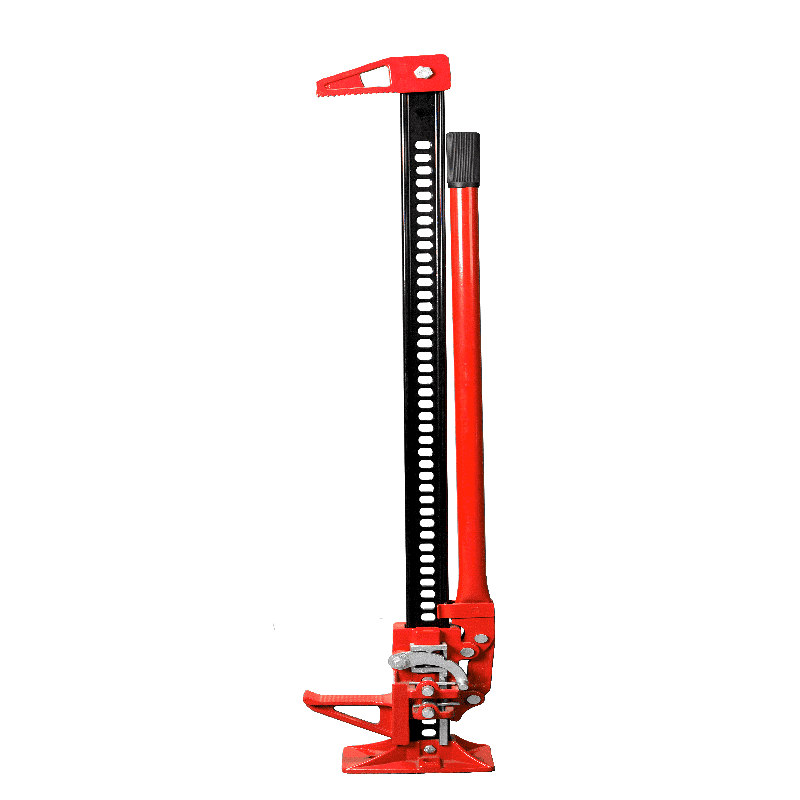

Farm Jack

- Making it ideal for off-road and farm use.

- Made of high-strength steel or cast iron, ensuring durability in tough conditions.

- Uses a manual ratchet system to lift and lower loads in a controlled manner

Jack Stand

Jack stands are essential safety tools used to support a vehicle or heavy load once it has been lifted by a jack. They are designed to prevent accidental drops and provide stable, long-term support while you work under the vehicle or load.

How to Use a Jack Safely?

Proper use of a jack is essential to ensure both your safety and the safety of the vehicle or load being lifted.

Pre-Use Inspection

- Hydraulic Fluid Check

- Support Point Check

- Jack Condition

Correct Placement of Jack

- Level Surface

- Jack Placement

- Avoid Tilting

Use Jack Stands for Safety

- Ensure Proper Adjustment

- Never work without Safety Support

Common Mistakes and Misure

- Lifting at the wrong point

- Overloading the jack

- Not Using Jack stands

- Not checking the ground

Frequently Asked Questions

A jack is used to lift a vehicle or heavy object, while a jack stand is used to support and hold the object once it has been lifted. adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation.

When purchasing a jack, consider the following factors:

- Weight Capacity: Ensure that the jack’s lifting capacity meets your needs, usually indicated by the maximum weight it can handle.

- Material and Craftsmanship: High-quality jacks are typically made of steel or aluminum, with no noticeable defects or corrosion.

- Lifting Mechanism: Check if the lifting mechanism operates smoothly, without sticking or resistance.

- Safety Features: Choose jacks with locking mechanisms or anti-slip bases to enhance stability during use.

- Brand Reputation: Opt for reputable brands or products with certifications to ensure better quality and durability.

For larger vehicles like SUVs and trucks, it is recommended to use a heavy-duty hydraulic jack or high-lift jack. These types of jacks typically have:

- Higher weight capacity, usually capable of lifting 3 tons to 5 tons or more.

- Larger lifting range, making them suitable for higher vehicles or larger ground clearance.

- Durability, able to withstand heavy loads and harsh usage conditions.

If a hydraulic jack is leaking oil, it usually means that the seals are damaged or there are cracks in the system. In this case, stop using the jack immediately to avoid further issues. Inspect the hydraulic seals, and if any are damaged, replace the seal or have it repaired. If there is significant oil leakage, you may need to refill the hydraulic fluid or consider replacing the jack.

Ready to lift safely and efficiently?

Explore our premium selection of jacks and jack stands designed for every need. Whether you’re working on a car, truck, or SUV, we’ve got the perfect tools to get the job done.