Lifting Chains: Reliable Solutions for Heavy-Duty Lifting and Rigging

A lifting chain is a heavy-duty, high-strength chain used for lifting and securing heavy loads in various industrial applications. It is commonly made from alloy steel or carbon steel, designed to withstand extreme tension and pressure during lifting operations. Lifting chains are often used in conjunction with other rigging equipment, such as hoists, winches, and cranes, to safely lift, transport, and secure materials, machinery, and other heavy items.

Classification and Applications of Lifting Chains

Understanding the Types and Characteristics of Lifting Chains from Strength Levels to Uses

| Classification | Specific Types | Features and Applications |

| By Strength Level | G30 Regular Chains | Low strength, suitable for light industrial or everyday use. |

| G43 High Strength Chains | Higher strength, suitable for towing and light lifting operations. | |

| G70 Transport Chains | Higher tensile strength, commonly used for securing goods or transport. | |

| G80 Lifting Chains | Industry standard for lifting, with excellent strength and durability, suitable for harsh environments. | |

| G100 High-Performance Chains | Stronger than G80, designed for high-demand lifting operations, requires stricter maintenance. | |

| G120 Ultra-High Strength Chains | Currently the highest strength, used in extreme environments or high safety scenarios. | |

| By Application | Lifting Chains | Designed for lifting and moving heavy loads, often used with hoists. |

| Securing Chains | Used for securing goods or vehicles, preventing movement or slippage. | |

| Anti-Skid Chains | Installed on tires to increase traction on icy or snowy surfaces. | |

| By Link Structure | Short-Pitch Chains | Higher stability, suitable for high-frequency lifting equipment. |

| Long-Pitch Chains | More economical for lighter or infrequent use scenarios. | |

| Welded Chains | Links are welded together, providing high strength for heavy-duty applications. | |

| Forged Chains | Links are forged, offering durability and strength, suitable for industrial environments. | |

| By Surface Treatment | Galvanized Chains | Excellent corrosion resistance, suitable for outdoor use. |

| Stainless Steel Chains | Strong corrosion resistance, suitable for food and chemical industries. | |

| Coated Chains | Coatings enhance protection and visibility, suitable for various environments. | |

| By Special Applications | Mining Chains | High tensile strength and wear resistance, specifically designed for mines. |

| Marine Chains | Used for anchor chains or mooring chains, capable of withstanding seawater corrosion and heavy loads. | |

| Explosion-Proof Chains | Meets explosion-proof requirements, suitable for flammable and explosive environments. |

Practical Applications of Lifting Chains

Construction

On construction sites, lifting chains are often used to lift heavy building materials such as steel beams, precast concrete parts, and large machinery

Ports

In ports, lifting chains are used to unload and load containers, ship parts, and heavy cargo. Chains are durable and corrosion-resistant, making them ideal for marine environments.

Industrial

In manufacturing and the automotive industry, lifting chains are used for assembling and transporting heavy machinery

Logistics

In warehousing and logistics, lifting chains are used to move and secure bulk cargo. They are often combined with pulleys, slings, and other accessories to ensure stability and safety during transportation.

Maintenance and Safe Operation of Lifting Chains

Usage Guide

How to Check for Wear and Proper Operating Procedures

Checking Listing

- Check for Wear

- Check Connecting Links and Hooks

- Operating Procedures

Maintenance Tips

Chain Cleaning and Corrosion Prevention

Maintenance Listing

- Cleaning the Chain

- Corrosion Prevention

- Storage

Frequently Asked Questions

Lifting Chains FAQ Section

How long do lifting chains last?

The lifespan of a lifting chain primarily depends on its usage frequency, load, operating environment, and maintenance. Typically, lifting chains can last up to 10 years or more, but if they are regularly overloaded or not properly maintained, their lifespan will be significantly reduced.

How can I identify the grade marking on a chain?

Chain grade markings typically follow the format “G” followed by a number (e.g., G80, G100), with the number indicating the chain’s load capacity. The higher the number, the stronger the chain.

Does the performance of lifting chains get affected in high-temperature environments?

High temperatures significantly affect the performance of lifting chains. Standard chains lose strength in high temperatures, potentially leading to breakage or deformation.

How can I prevent chain twisting during lifting?

Always keep the chain vertical during lifting, avoid friction with sharp surfaces, and use appropriate lifting accessories. Ensure chains are of equal length and load is evenly distributed when using multiple chains.

Maximize Your Lifting Efficiency with Quality Chains

Choose High-Quality Lifting Chains for Safety and Performance

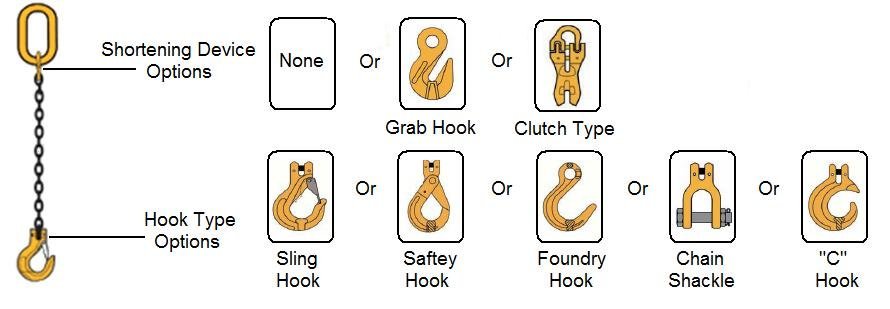

Lifting Chain Components

G80 and G100 components available.Such as eye type hooks, clevis type hooks, grab hooks, connecting link, master link, master link assembly etc.

Contact Us for more details.