Lifting Clamps for Safe and Efficient Lifting

Lifting clamps are indispensable tools for handling heavy materials like steel plates, pipes, and beams. Explore our range of lifting clamps designed to meet the toughest challenges in material handling.

Types of Lifting Clamps

From vertical to horizontal clamps, our wide selection caters to various lifting needs. Whether you’re handling steel plates, pipes, or beams, we offer lifting clamps that ensure a secure grip and optimal performance.

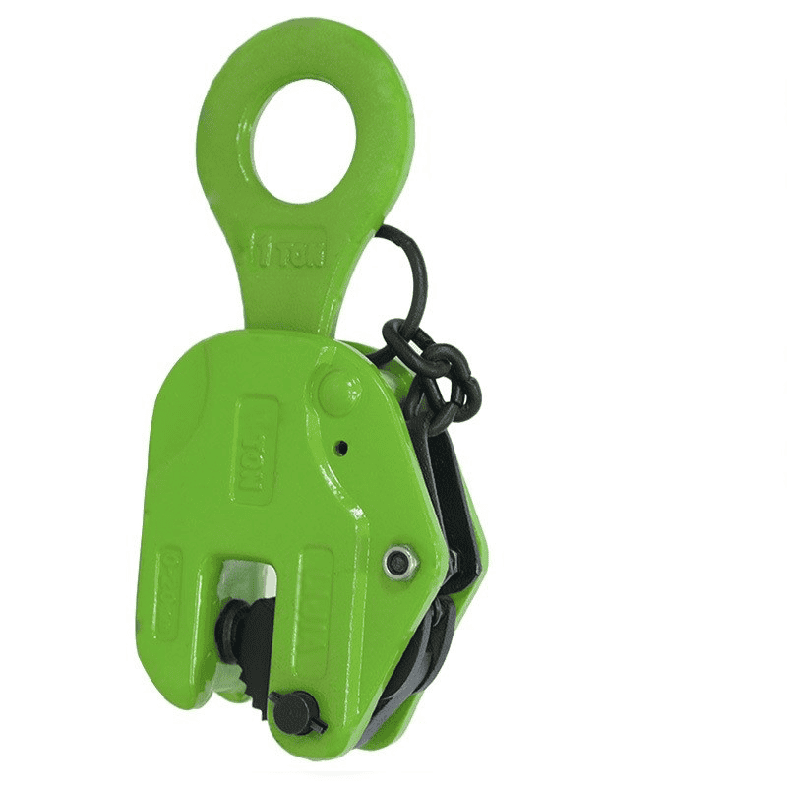

Vertical Lifting Clamps

For lifting plates in a vertical position.

Beam Clamps

For securing to structural beams.

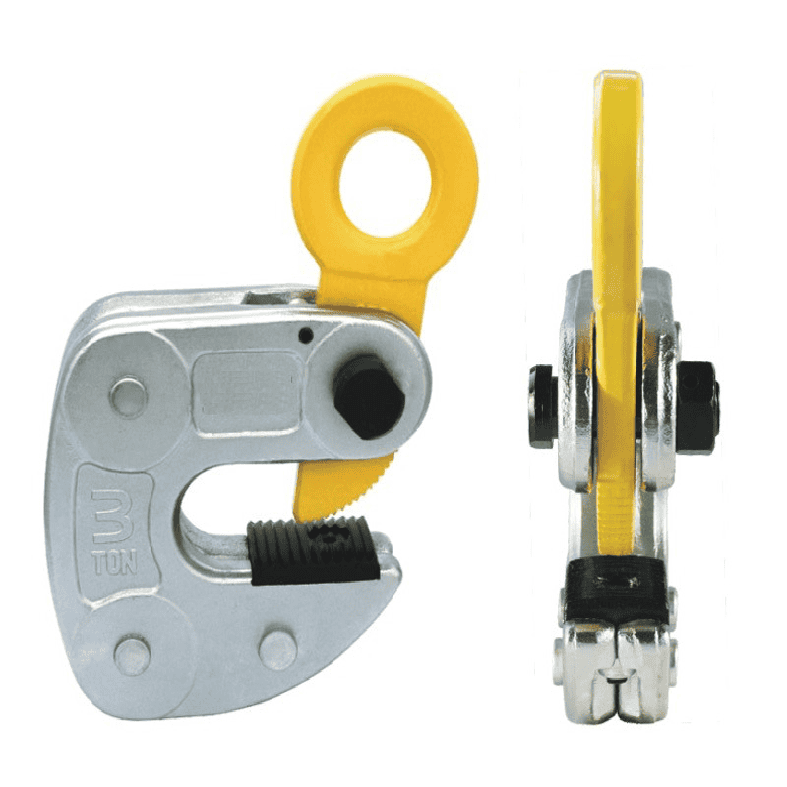

Horizontal Lifting Clamps

Designed for lifting plates horizontally.

Pipe Lifting Clamps

Specialized for cylindrical loads

Applications of Lifting Clamps

Lifting clamps are a cornerstone of efficiency across multiple industries.

Construction

Lifting clamps are essential for moving heavy construction materials such as steel beams, concrete panels, and precast elements.

Manufacturing

In manufacturing facilities, lifting clamps facilitate the movement of large components during assembly processes.

Shipbuilding

Lifting clamps play a crucial role in the shipbuilding industry by handling large metal plates and components required for hull construction.

Logistics

In logistics and warehousing, lifting clamps are used to load and unload heavy goods from trucks and containers.

Features of Lifting Clamp

Safety First

Our lifting clamps come equipped with advanced safety features such as locking mechanisms and overload protection to ensure secure handling at all times.

Durability d

Built from high-quality materials, our clamps are designed for heavy-duty use, providing long-lasting performance even in demanding environments.

Ease of Use

With user-friendly designs, our clamps can be easily attached and detached from loads, streamlining your workflow.

Safety Tips for Using Lifting Clamps

Ensuring safety when using lifting clamps is crucial to prevent accidents and extend the equipment’s lifespan.

Inspect Before Use

①Check for wear, cracks, or deformation in the clamp. ②Inspect locking mechanisms and gripping surfaces for proper functionality.

Follow Load Limits

①Always adhere to the clamp's rated load capacity. ②Avoid overloading or using clamps with damaged components.

Secure Attachment

①Ensure the clamp is properly aligned with the load. ②Verify the load is balanced and securely gripped before lifting.

Safe Operation

①Avoid standing under suspended loads. ②Lift and lower the load slowly to maintain stability.

Frequently Asked Questions.

Yes, but it depends on the type of clamp and the coating. Some clamps are designed with soft grips to minimize damage to painted or coated surfaces. Always verify that the clamp is suitable for the specific surface before use to avoid slippage or damage.

- Check for visible signs of wear, cracks, or deformation.

- Inspect locking mechanisms to ensure they function properly.

- Look for worn or damaged gripping surfaces.

- Verify that all bolts and pins are secure and free of corrosion.

It depends on the clamp type. Horizontal lifting clamps are designed for horizontal loads, while vertical lifting clamps are for vertical lifting. Some models are multipurpose and can handle both, but always confirm with the product specifications.

Most lifting clamps are designed to work with standard hoisting systems, but compatibility depends on the clamp type and the hoist’s specifications. Always ensure that the hoisting system’s capacity and attachment points match the clamp’s requirements.

- Stop the operation immediately.

- Lower the load safely and inspect the clamp for damage or improper attachment.

- Ensure the gripping surfaces are clean and the load is balanced correctly before reattaching the clamp.