Lifting Sling Colors: What They Mean for WLL, Durability, and Safe Use

- Lifting Sling Colors: What They Mean for WLL, Durability, and Safe Use

- The Relationship Between Color and WLL

- Does Color Affect the Durability of Lifting Slings?

- Why Do Lifting Sling Colors Become Lighter Over Time?

- Can a Faded Lifting Sling Still Be Used?

- How to Prevent Premature Color Fading

- Common Misunderstandings About Sling Colors (FAQ)

- Conclusion: Using Color Correctly Improves Safety

The colors on lifting slings are far more than visual decoration—they serve as a critical safety language on the job site. Different colors correspond to different Working Load Limits (WLL), allowing operators to quickly identify and select the correct sling, thereby preventing misuse from the start. However, in practical use, color is often misunderstood—particularly when it comes to durability, fading, and how to respond when fading occurs.

This article explains the relationship between sling color and WLL, examines whether color affects product lifespan, analyzes the causes of fading, and provides clear guidelines for handling faded slings.

The Relationship Between Color and WLL

Color as a quick identification tool

For webbing slings and round slings—particularly those manufactured according to EN 1492 standards—colors are commonly used to indicate the Working Load Limit (WLL). This allows users to identify sling capacity at a glance, even in busy or low-visibility environments.

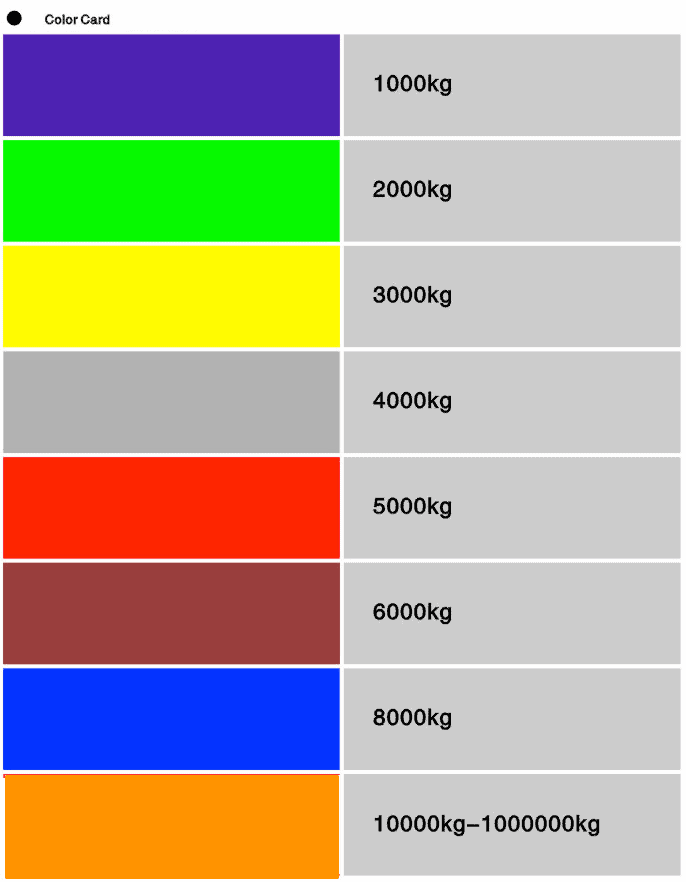

Typical EN color coding includes:

- Purple – 1 ton

- Green – 2 tons

- Yellow – 3 tons

- Grey – 4 tons

- Red – 5 tons

- Brown – 6 tons

- Blue – 8 tons

- Orange – 10 tons

An important safety reminder: Color is only a quick reference. The actual WLL must always be confirmed by the lifting slings label.

Does Color Affect the Durability of Lifting Slings?

Color itself does not determine strength

A common misconception is that darker colors are stronger or more durable. In reality, the load-bearing capacity and durability of a lifting sling depend on:

- The base material (polyester, nylon, etc.)

- Yarn quality and weave structure

- Stitching design and manufacturing process

Color alone does not increase or reduce strength.

Why Do Lifting Sling Colors Become Lighter Over Time?

Color fading is a common and natural process during service life. The most frequent causes include:

1) UV exposure

Prolonged exposure to sunlight is the primary reason for color fading, especially in outdoor lifting operations. UV radiation gradually breaks down dye molecules and surface fibers.

2) Chemical contact

Acids, alkalis, solvents, and industrial chemicals can react with dyes and fibers, often causing discoloration before visible structural damage appears.

3) Abrasion and friction

Repeated contact with rough or sharp surfaces wears down outer fibers, leading to localized fading and thinning of the webbing.

4) Improper cleaning

High-temperature washing or aggressive detergents can strip dye from fibers and weaken the sling structure.

Can a Faded Lifting Sling Still Be Used?

Fading does not automatically mean the sling must be scrapped. A lighter color alone is not an absolute criterion for immediate disposal, but it should always be treated as a clear warning sign.

A comprehensive assessment must be made alongside other indicators.

For slings showing signs of fading, the following key items should be carefully inspected:

- Signs of surface cuts, tears, or broken fibers

- Wear or loose stitching at seams

- Evidence of chemical burns or material hardening

- Illegible or missing identification labels

If fading is accompanied by mechanical damage or unreadable labels, the sling must be taken out of service immediately.

How to Prevent Premature Color Fading

Although fading cannot be completely avoided, good practices can significantly slow it down:

Proper storage

- Store slings away from direct sunlight

- Keep in a dry, well-ventilated area

- Avoid contact with chemicals during storage

Correct use

- Protect slings from sharp edges using corner protectors

- Avoid dragging slings across rough surfaces

- Never tie knots in webbing slings

Choose quality-manufactured slings

- UV-resistant dyes

- Consistent dye penetration

- Durable and clearly printed labels

High-quality manufacturing not only improves appearance but also extends service life and safety margins.

Common Misunderstandings About Sling Colors (FAQ)

Does a darker color mean higher strength?

No. Strength depends on material and construction, not color depth.

If two slings have the same color, do they have the same WLL?

Not necessarily. Always check the label, especially when standards differ.

Does fading always mean strength loss?

Not always, but it may indicate exposure that could affect strength. Inspection is required.

Can I rely only on color to select a sling?

No. Color is a guide—labels and certificates are mandatory references.

Conclusion: Using Color Correctly Improves Safety

Lifting sling colors play a valuable role in fast identification and safer lifting operations. However, true safety comes from understanding what color can—and cannot—tell you.

- Color helps identify WLL quickly

- Labels provide the final authority

- Fading is a warning, not a verdict

- Regular inspection is essential

By combining informed color awareness with proper inspection and storage practices, lifting slings can be used more safely and efficiently throughout their service life.