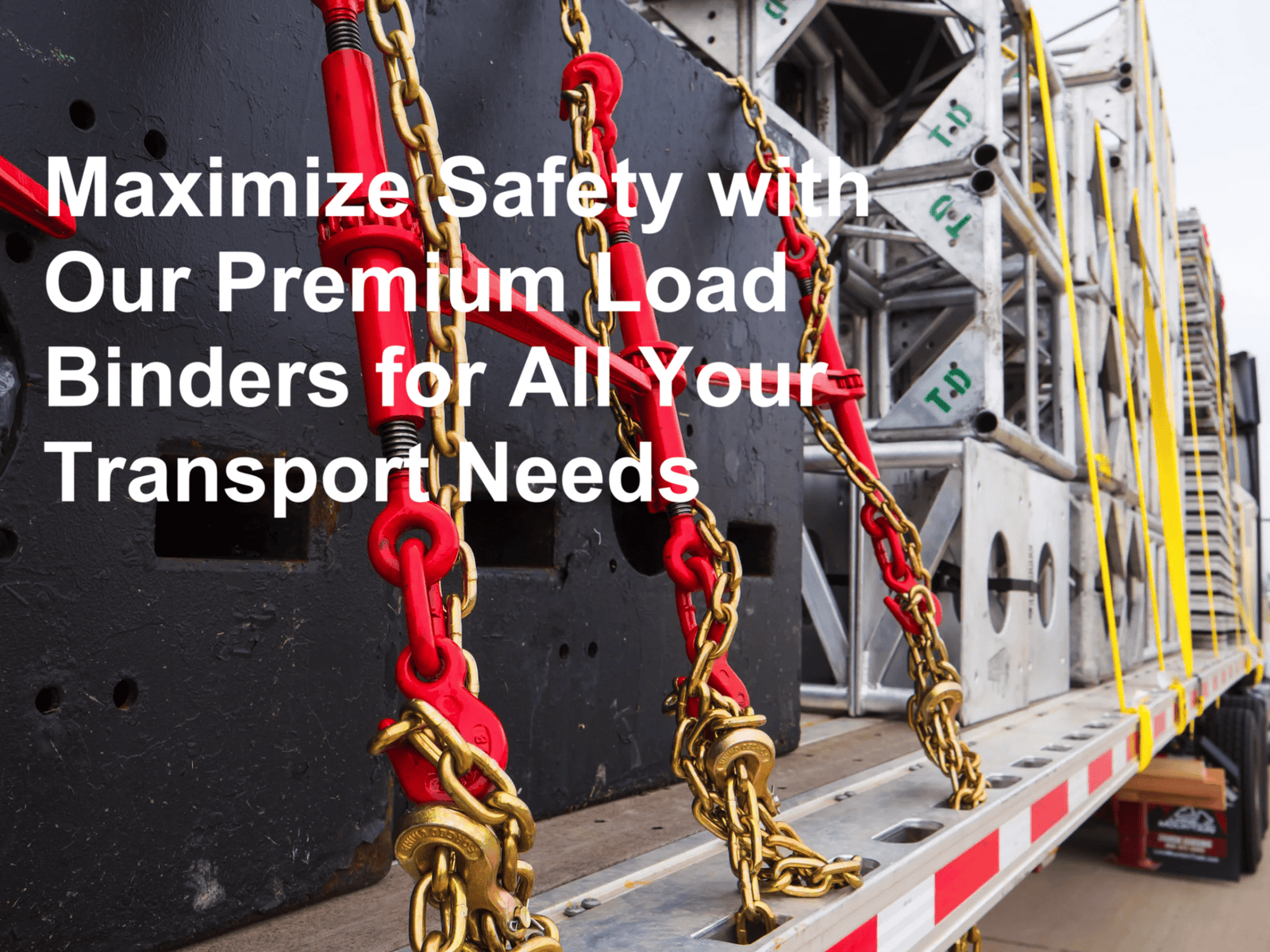

Heavy-Duty Loadbinders for Secure Cargo Fastening

Reliable and Efficient Solutions for Tightening and Securing Your Load with Ease

Type of Load Binder

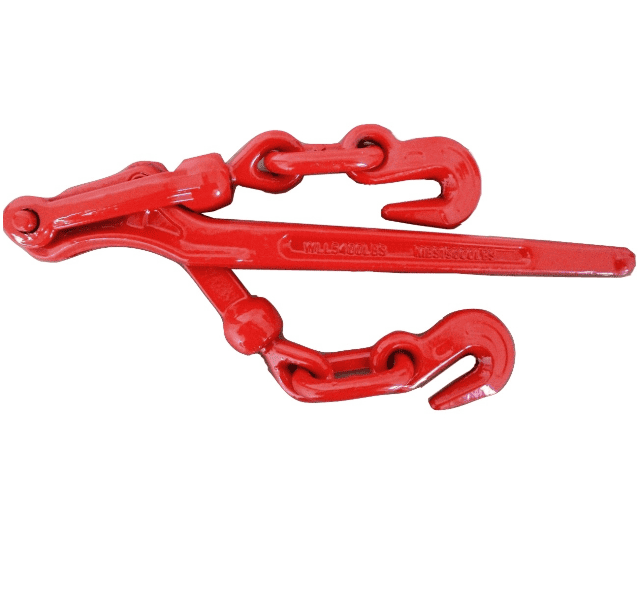

Lever Type Load Binder

These load binders use a lever to apply tension to the chain or strap. The lever action helps to tighten the load quickly and efficiently, making them suitable for heavier loads.

Ratchet Load Binder

These use a ratcheting mechanism to gradually tighten the load. The ratchet ensures secure tensioning, offering greater control over how tightly the load is fastened.

Spring Type Load Binder

A Spring Load Binder is a type of load binder equipped with a spring mechanism that helps to apply tension and securely fasten cargo during transportation. The spring feature ensures the binder remains under constant tension, offering a reliable and efficient method for securing heavy or bulky loads.

Product Features

Strength, Durability, and Safety Combined for Your Cargo Protection

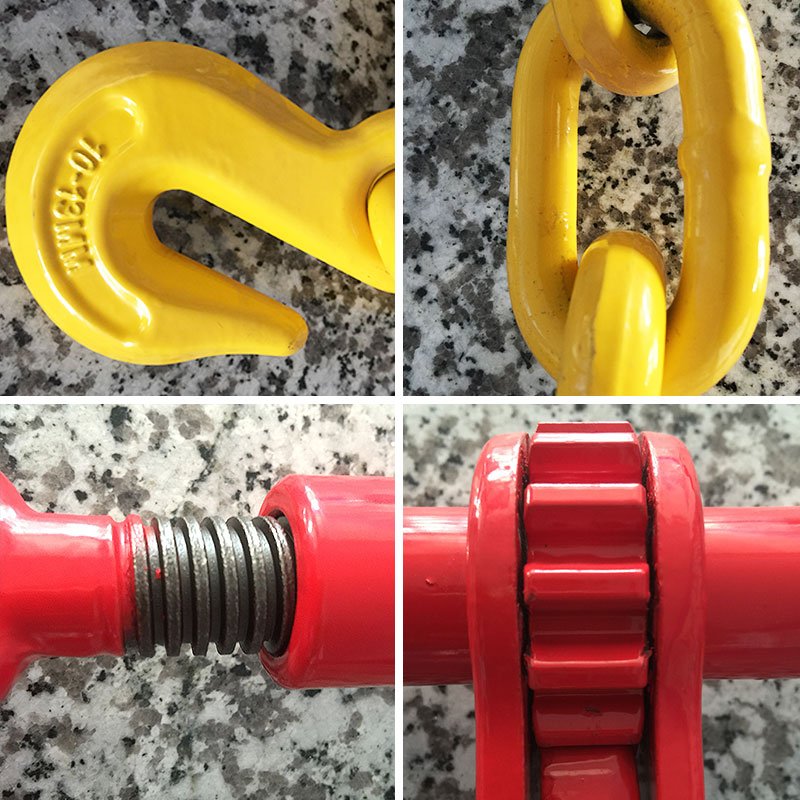

High Strength and Durability

Made from heavy-duty materials that ensure long-lasting performance.

Easy to Use

Simple mechanisms that can be operated manually to quickly tighten and secure your cargo.

Versatile

Suitable for a wide range of applications, including trucks, trailers, and containers.

Corrosion-Resistant

Designed to withstand harsh environmental conditions, ensuring longevity.

Safety

Built with safety features to prevent accidents during tightening and use.

Applications: Where Can You Use Loadbinders?

Transporation

For securing large and heavy items during transport.

Construction

Used for fastening equipment and materials during transit.

Industrial

Essential for securing cargo in containers or on vessels

Safety and Maintenance Tips

Safety Tips

- Always check the load binder for signs of wear before use, including the mechanism and handles.

- Never exceed the load rating of the binder to avoid accidents or failures.

- Ensure the load is evenly distributed and securely fastened before transportation.

Maintenance Tips

Clean your load binder after each use and lubricate moving parts to prevent corrosion.

Frequently Asked Questions

Loadbinders are primarily designed for use with chains that meet specific grade requirements (such as Grade 70, or 80). They are generally not recommended for use with ropes, as ropes may not provide the necessary strength or compatibility. Always verify the compatibility of your loadbinder with the specific chain type.

The maximum load capacity, or working load limit (WLL), varies by loadbinder model. It typically ranges from 5,000 lbs to over 20,000 lbs, depending on the binder’s size, material, and design. Always refer to the product specifications and never exceed the stated WLL.

Yes, our loadbinders are designed with corrosion-resistant finishes, such as galvanized or powder-coated surfaces, making them suitable for outdoor use in harsh weather conditions. They perform reliably in rain, snow, and marine environments, ensuring long-term durability and strength.

Proper maintenance ensures the longevity and safety of your loadbinder:

- Regularly inspect the binder for wear, cracks, or deformation.

- Clean off dirt, grease, and debris after use.

- Lubricate moving parts, such as hinges and threads, to prevent corrosion and ensure smooth operation.

- Store the loadbinder in a dry place to avoid moisture damage.