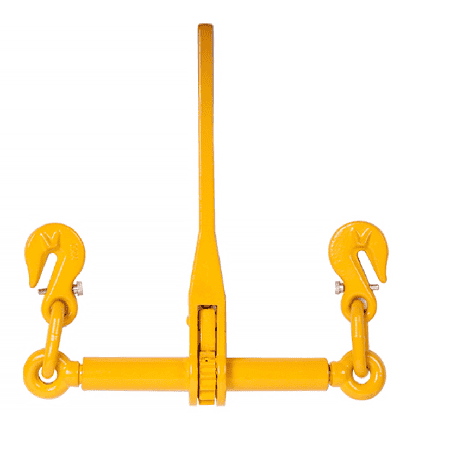

Why Storage and Maintenance Matter

Ratchet straps are essential for safe cargo transport, but improper storage leads to tangles, mold, and early wear. For truckers and logistics pros, smart storage means longer-lasting gear and smoother jobs.

How to Prevent Tangling

Tangled straps waste time and wear out faster.

Common Problems

- Straps knot up after use

- Time lost untangling before jobs

- Permanent creases weaken straps over time

Solutions:

- Always release all tension after use

- Start rolling from the hook end, keeping the strap straight

- Use bands or storage aids to prevent the roll from unraveling

- Avoid storing straps loosely with other tools

How to Avoid Mold During Long-Term Storage

Why Mold Happens:

- Humid storage areas with poor ventilation

- Moisture or oil left on the strap after use

- Stored on the floor or in sealed plastic boxes

Proper Storage Tips:

- Wipe straps dry with a clean cloth after use

- Use a mild cleaner if there’s oil or grime

- Make sure the straps are completely dry before storing

- Store in a cool, dry, and ventilated place

- Add silica gel packs or a small dehumidifier in the storage area

Tips for Ratchet Strap Care – What to Do (& Avoid)

Do This

Clean & lubricate ratchets – Wipe dirt off mechanisms and apply light oil to prevent rust.

Inspect every 3 months – Check for mold, fraying, stiffening, or excessive wear.

Store in a dry place – Avoid damp areas to prevent mildew and corrosion.

Avoid This

⚠️ Storing under heavy weight – Can deform straps and buckles over time.

⚠️ Leaving straps tightened – Causes unnecessary stress and weakens fibers.

⚠️ Ignoring damage – Frayed or hardened straps are safety risks—replace them.

Smart Storage = Safer, Longer-Lasting Straps

Do you need the Ratchet Strap Storage Checklist? Contact us for a download