Lifting Chain Slings: A Guide to Safe, Durable Lifting Solutions and Selection Tips

- Lifting Chain Slings: A Guide to Safe, Durable Lifting Solutions and Selection Tips

- What is a lifting chain sling?

- Components of a lifting chain sling

- Types of lifting chain slings

- How do you choose the right lifting chain sling?

- Precautions for using lifting chain slings

- Maintenance and care of lifting chain slings

- Conclusion

Lifting Chain Slings are a vital piece of lifting equipment in the industrial and construction sectors. They are used to safely lift and move heavy objects, providing a strong, durable solution, especially in environments where heavy weight and strength are required.

What is a lifting chain sling?

Lifting chain slings are lifting tools consisting of chains and related lifting accessories (such as hooks, connecting rings, and connecting chains). They are designed to lift heavy objects from one location to another and are commonly found in construction sites, factories, ship repairs, and other places where heavy lifting is required.

Compared with other types of lifting equipment, chain slings have higher load capacity, wear resistance, and corrosion resistance, making them ideal for extreme working environments. They are usually made of alloy steel (such as G80, G100) to ensure sufficient strength and durability.

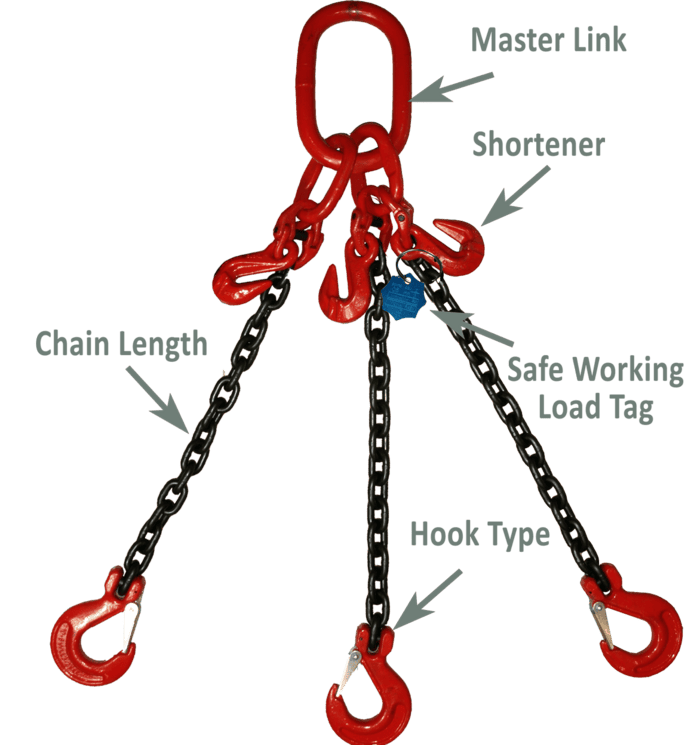

Components of a lifting chain sling

Chain: The main load-bearing part of the sling, is usually made of alloy steel chain. G80 and G100 are the most common specifications, representing different strength levels.

Hook: The hook is the connection point for lifting, and there are usually different types, such as eye hooks and grab hooks.

Terminal accessories: Includes accessories such as connecting rings, catchers, and locks to increase the stability and safety of the sling.

Types of lifting chain slings

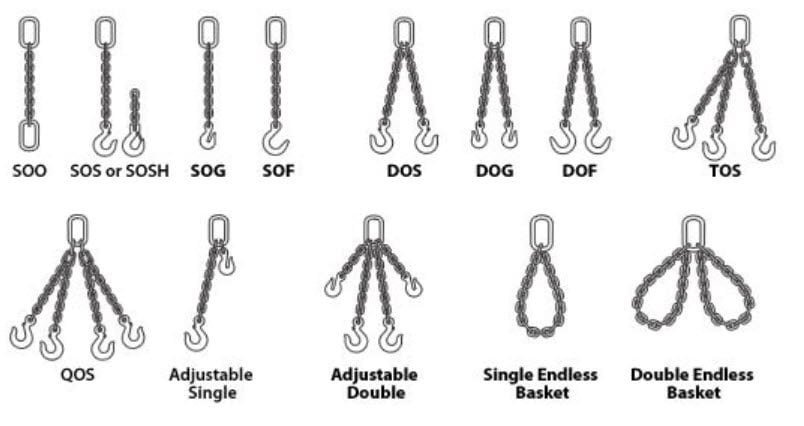

Depending on the lifting requirements, lifting chain slings can have different configurations, common types include:

Single-leg chain slings: suitable for lifting small or single loads, usually used to lift smaller objects.

Double-leg/multi-leg chain slings: suitable for lifting larger loads, can provide more stability and reduce instability during lifting.

Chain slings with poles: This type of sling is equipped with a horizontal pole, which can make the lifting process more balanced and avoid direct contact with the load surface, reducing wear.

How do you choose the right lifting chain sling?

Choosing the right lifting chain sling is crucial to ensure safe lifting. Here are a few key factors to consider when purchasing:

Load capacity: Choose the appropriate chain sling according to the weight of the lifting object. Generally, the rated load capacity of the sling can be found on its label. Make sure the selected sling can withstand the required load.

Lifting angle: The angle of the sling affects its load-bearing capacity. Generally, the larger the lifting angle (close to vertical), the higher the load capacity of the sling.

Sling length: Choose a sling of the appropriate length according to the height and needs of the lifting operation. A sling that is too short may not provide enough space, and a sling that is too long may cause inconvenience in operation.

Environmental conditions: Suppose the lifting operation is carried out in extreme environments (such as high temperature, low temperature or chemical corrosion, etc.). In that case, special materials and protective measures that adapt to these conditions need to be selected.

Precautions for using lifting chain slings

To ensure the safety of lifting operations, here are some things to note when using lifting chain slings:

Regular inspection: Before each use, always check the condition of the chain sling. Check the chain for signs of wear, cracks, or corrosion. If any problems are found, stop using it immediately and repair or replace it.

Load balance: During the lifting process, ensure that the load is evenly distributed. If the center of gravity of the hoisted object is not in the center of the sling, it may cause uneven force on the chain sling, resulting in an accident.

Avoid overloading: Never load the sling with a load exceeding its rated load capacity. Overloading the sling will not only cause damage to the equipment but may also pose a safety hazard.

Correct operation: When using a chain sling, the operator should receive professional training to understand how to operate the sling correctly to avoid accidents caused by improper operation.

Maintenance and care of lifting chain slings

To extend the service life of lifting chain slings and ensure that they always maintain optimal performance, regular maintenance and care are essential:

Regular cleaning: Keep the slings clean and avoid the accumulation of oil, dirt, or other corrosive substances.

Storage environment: The slings should be stored in a dry and clean environment and avoid long-term exposure to wet or corrosive environments.

Regular inspection and replacement: Regularly check the condition of the chain slings. If wear, corrosion, or cracks are found, they should be replaced in time.

Conclusion

Lifting chain slings are key tools to ensure safe and efficient lifting operations. By choosing the right sling, following operating specifications, and performing regular inspections and maintenance, you can effectively reduce the risk of accidents and improve work efficiency. Always remember that safety is the primary consideration for any lifting operation.