Top 10 FAQs about ratchet load binders

When transporting heavy cargo, ensuring the safety and stability of the load is critical. The ratchet load binder is a widely used tool in trucking, construction, and other heavy-duty load-securing applications, offering strong tensioning power with simple operation. However, many people still have questions about how to choose, properly use, and maintain ratchet load binders.

This article compiles the top 10 most frequently asked questions about ratchet load binders and provides detailed answers. Whether you’re a beginner or an experienced user, you’ll find practical tips to ensure safe and secure load fastening.

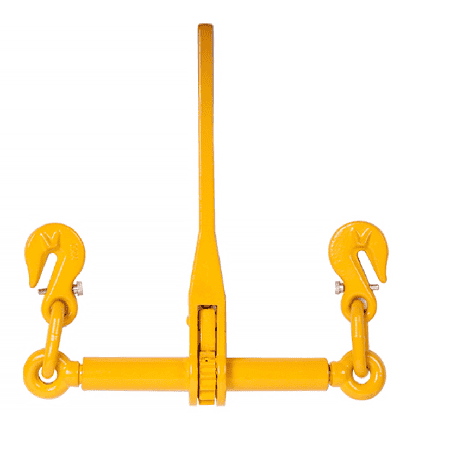

Q1: How do ratchet load straps work?

Ratchet load straps work similarly to a ratchet system. The user adjusts the tension of the strap or chain using the ratchet rotator, which tightens the strap by gripping the chain with the ratchet, keeping the load securely fixed to the transport platform.

Q2: What does the rated pull (WLL) of a ratchet load tie mean?

The rated pull (WLL, Working Load Limit) refers to the maximum working load that the ratchet load tie can withstand when used safely. Using a ratchet load tie exceeding the rated pull may cause damage or safety accidents.

Q3: How to use ratchet load straps correctly?

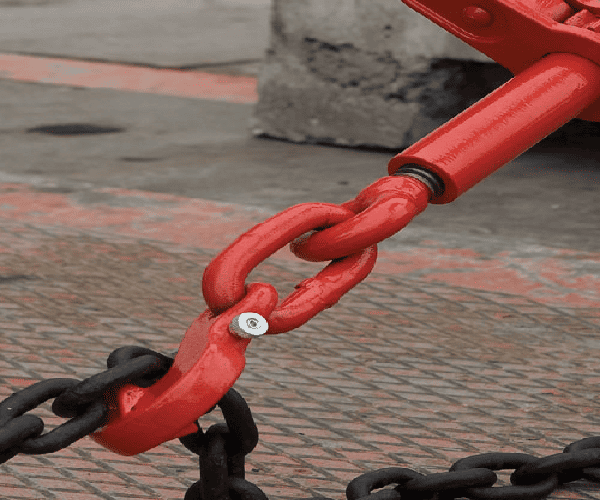

- Pass the chain or strap through the fixed point and through the load.

2. Use the ratchet device to rotate and make sure the chain or strap is fully tightened.

3. Make sure the strap is not loose or slipping, and make any necessary adjustments.

4. Check that the chain and ratchet are secure after tightening and confirm that there is no looseness.

Q4: How to maintain and care for ratchet load straps?

- Check the ratchet mechanism regularly to ensure it is working properly.

2. Clean the ratchet load straps to avoid the accumulation of dirt and moisture.

3. Check the straps and chains for wear, cracks or damage.

4. Avoid long periods of load when storing, preferably in a dry, cool place.

5. Check that the hooks are intact and avoid deformation or rust.

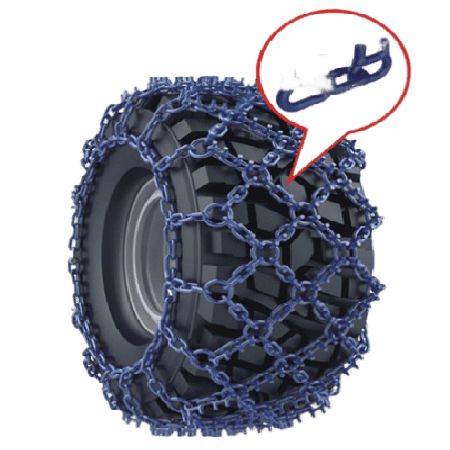

Q5: Are ratchet load straps suitable for all types of cargo?

Ratchet load straps are suitable for the transport of most cargo, especially large and heavy cargo. They are ideal for transporting items that require a high level of securing force, such as machinery, steel and building materials. However, for some more fragile or vulnerable items, other types of securing tools may be required.

Q6: How to tell if a ratchet load strap is overloaded?

If a ratchet load strap exhibits the following conditions during use, there may be a risk of overloading:

- The ratchet fails to tighten or rotate.

2. The strap or chain is visibly deformed, cracked, or worn.

3. The tensioner or hook is loose or deformed.

4. Unusual noise or resistance is heard during use.

Please stop using the strap immediately and replace it.

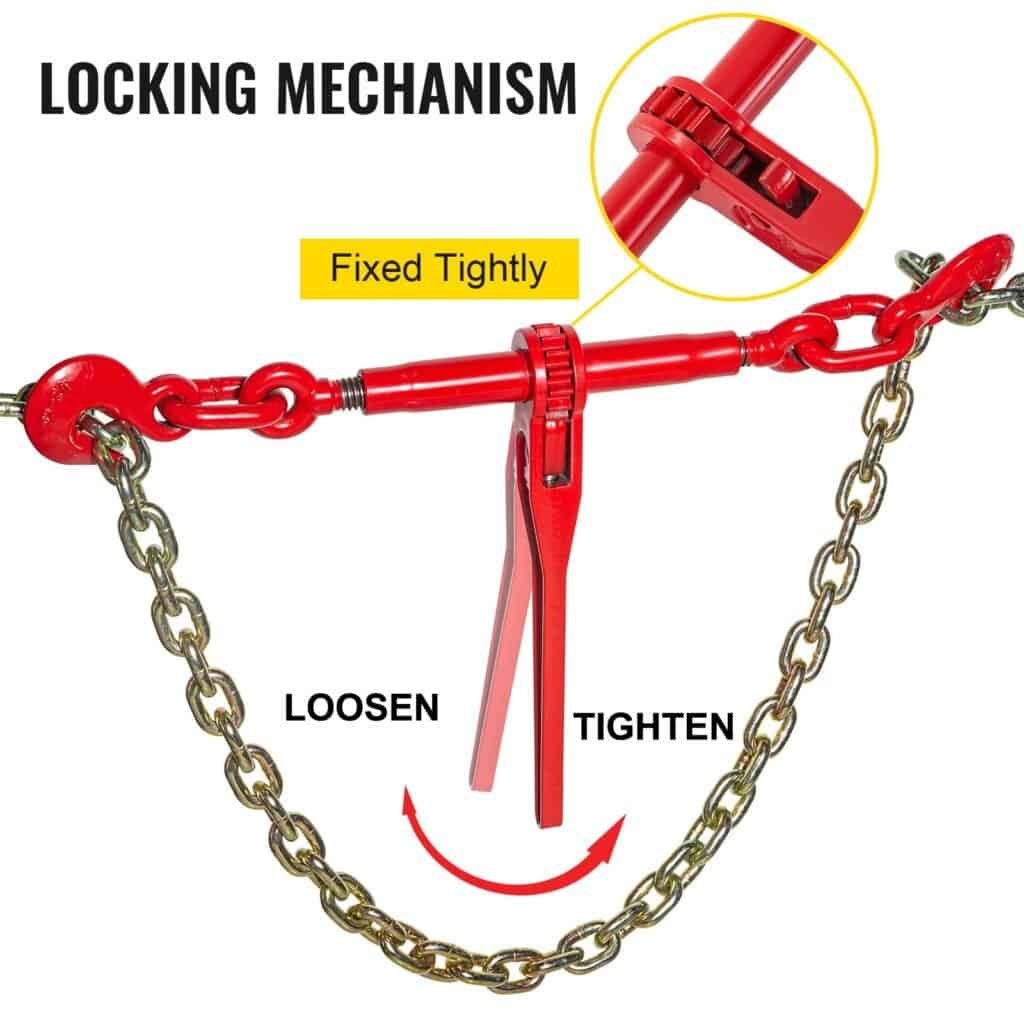

Q7: How do I release a ratchet load strap safely?

To release a ratchet load strap, follow these steps:

First, unlock the ratchet to avoid a sudden release that could cause the strap to rebound.

Slowly rotate the ratchet to gradually loosen the strap.

Make sure the load is not affected and check the safety of the strap and chain.

Q8: Ratchet load strap problems and solutions

Ratchet stuck or not turning:

It may be because of dust or corrosion accumulated inside the ratchet. The solution is to clean the ratchet and apply some lubricant.

Strap slipping:

If the strap slips during use, it may be because the strap is too loose or not installed correctly. Check whether the strap is installed correctly and make sure that the ratchet is fully stuck.

Strap or chain damage:

Check the strap and chain for wear or cracks, check them regularly, and replace damaged parts in time.

Q9: Storage recommendations for ratchet load straps

Dry storage: Store ratchet load straps in a dry, ventilated place to avoid humid environments that may cause rust on metal parts.

Avoid high temperatures: Avoid exposing the straps to extreme heat to prevent deformation or aging of the material.

Avoid excessive loads: When storing for a long time, avoid putting loads on ratchet load straps, which will affect their service life.

Q10: Use Tips and Practices

Avoid Overloading: Each ratchet load strap has a rated pull force (WLL). Make sure the load does not exceed this limit to avoid breakage or damage.

Balance the Load: Make sure the straps are evenly distributed across the load to reduce stress concentration.

Avoid Cross-Using: Avoid cross-using multiple ratchet load straps, as this may cause an unstable load.

Check When Tightening: When tightening a load with a ratchet load strap, check for looseness or slippage and adjust if necessary.

Avoid Over-Tightening: Avoid excessive force when tightening. Make sure the item is firmly fixed. Over-tightening may cause damage to the straps or the load.

If you have any more questions or need further assistance, feel free to reach out!